Creating Optimal Solutions

Co-engineering

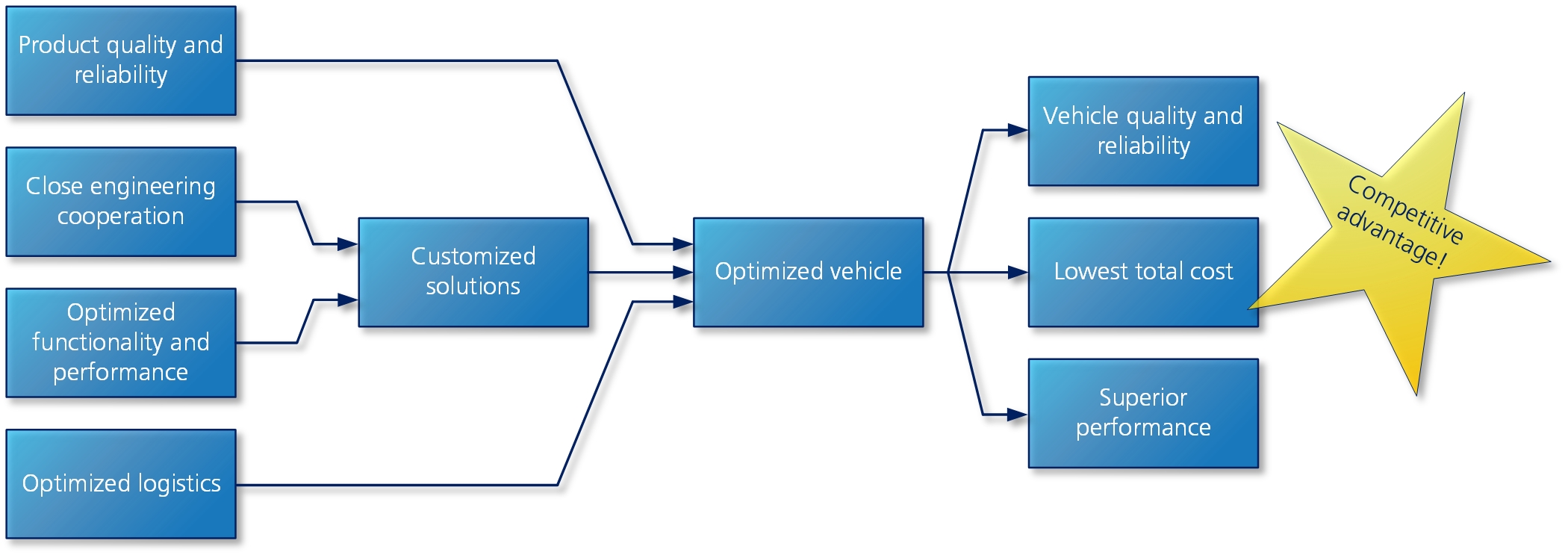

In today's competitive market, an industrial vehicle must perform optimally; each component in the control system of the vehicle must be perfectly integrated into the system. Inmotion has long experience with vehicle electrification, and we are able to support our OEM customers to achieve an optimal solution for each vehicle.

According to the needs of each customer and project, we can function as a component supplier, or we can take a larger responsibility for comprehensive design of the vehicle control system. In the extreme case, we have delivered turn-key control systems for the entire vehicle.

Regardless of each customer's needs though, we are always happy to provide our support in order to optimize integration and to ensure that the vehicle fulfills its potential and is successful in the market.

Flexible platform products

Although we can offer off-the-shelf solutions, we have found that most of our OEM customers need modifications to some extent to ensure that their vehicle functions to its full potential. Modifications of our standard products, rather than designing a new product from scratch to customer's specification, is what we call co-engineering.

Inmotion's flexible hardware and software platforms are designed to allow co-engineering of optimal solutions, while maintaining the advantage of a shared platform, both in terms of volume and in terms of "mileage" (proactive quality work and hours in the field ensure that bugs and quality defects are taken out of the product).

For almost all projects we do modifications to our software, ranging from simple setup of default parameters (so the OEM does not have to download parameter sets in their production) to customization of error handling and addition of customer-unique software algorithms. Our proprietary embedded software platform is modularized accordingly, with a clearly defined application interface to allow customization without compromising the integrity of the standard, basic functionality of the unit.

If required, and if the investment can be justified, we are also able to offer customization of hardware and mechanics of our components.

Dedicated resources

In our regional sales and application centers, we have dedicated teams of engineers that are specifically tasked with co-engineering in customer projects. This allows us to offer our customers rapid support in local language and without time-zone differences. When needed though, the specialists of the design centers will of course also be called in to further support customers and local engineering teams.

Life cycle support

Our support does not stop at the design phase. We understand the requirements of vehicle's long life and will support our customers also through the mass production, service and aftermarket phases of a vehicle life cycle.